Do You Get Paid for Welding School?

Introduction

Welding is a lucrative career, offering excellent job security and earning potential. However, the journey to becoming a skilled welder often starts with welding school, which requires both time and money. A common question among aspiring welders is whether they can get paid while attending welding school. The answer depends on various factors, including the type of program, available opportunities, and financial aid options. Let’s explore this topic in detail.

Understanding Welding School Costs

Before exploring opportunities to earn money during welding school, it’s crucial to understand the financial investment involved in pursuing this career path. Welding school costs can vary widely depending on factors like program type, length, location, and additional requirements. Let’s break down these costs to give you a clearer picture.

Tuition Fees

Tuition is the largest expense for most students. Short-term certificate programs focusing on foundational welding skills typically cost between $3,000 and $10,000. These programs are ideal for those looking to enter the workforce quickly. Associate degree programs, which include advanced welding techniques, general education courses, and transferable credits, range from $10,000 to $25,000. Specialized training programs, such as underwater welding or robotic welding, can cost as much as $40,000 due to the advanced skills and equipment required.

Equipment and Supplies

Beyond tuition, welding students need to purchase essential tools and safety gear. A high-quality welding helmet can cost anywhere from $50 to $500, while gloves, jackets, and boots add another $100 to $300. Basic tools like wire cutters, brushes, and filler materials may cost $100 to $300. These initial investments are necessary to participate in hands-on training and ensure safety during practice.

Certification Exams

Certification is a critical step for welding professionals, as it demonstrates competency and enhances employability. Exam fees range from $50 to $300 depending on the certification type, with specialized certifications costing even more. Some programs include these fees in tuition, but many do not, so students should budget for them separately.

Housing and Living Expenses

For those attending welding schools away from home, housing and living expenses can be a significant part of the overall cost. Rent in urban areas can range from $800 to $1,500 per month, while rural locations may be more affordable. Students also need to account for food, utilities, and transportation, which can add $500 to $1,000 per month.

Hidden Costs

Some expenses are less obvious but equally important. For example, students may need health insurance if their program requires it, adding $100 to $500 per month. Technology, such as laptops or software for online coursework, can also increase costs, especially for programs with digital components.

Total Cost Estimate

When all these expenses are considered, the total cost of attending welding school can range from $5,000 to over $40,000, depending on the program and individual circumstances. While this may seem daunting, it’s important to view welding education as an investment. The potential for high-paying jobs and long-term career stability makes the financial commitment worthwhile for many aspiring welders.

Understanding these costs upfront allows prospective students to plan their finances effectively, explore financial aid options, and consider paid opportunities to offset expenses. With proper budgeting and preparation, welding school can be a manageable and rewarding step toward a successful career.

Do You Get Paid for Welding School?

Paid Opportunities During Welding School

While attending welding school is typically an investment, there are several opportunities to earn money while you learn. These options not only help offset the costs of education but also provide valuable real-world experience to prepare students for a successful career in welding.

Apprenticeships

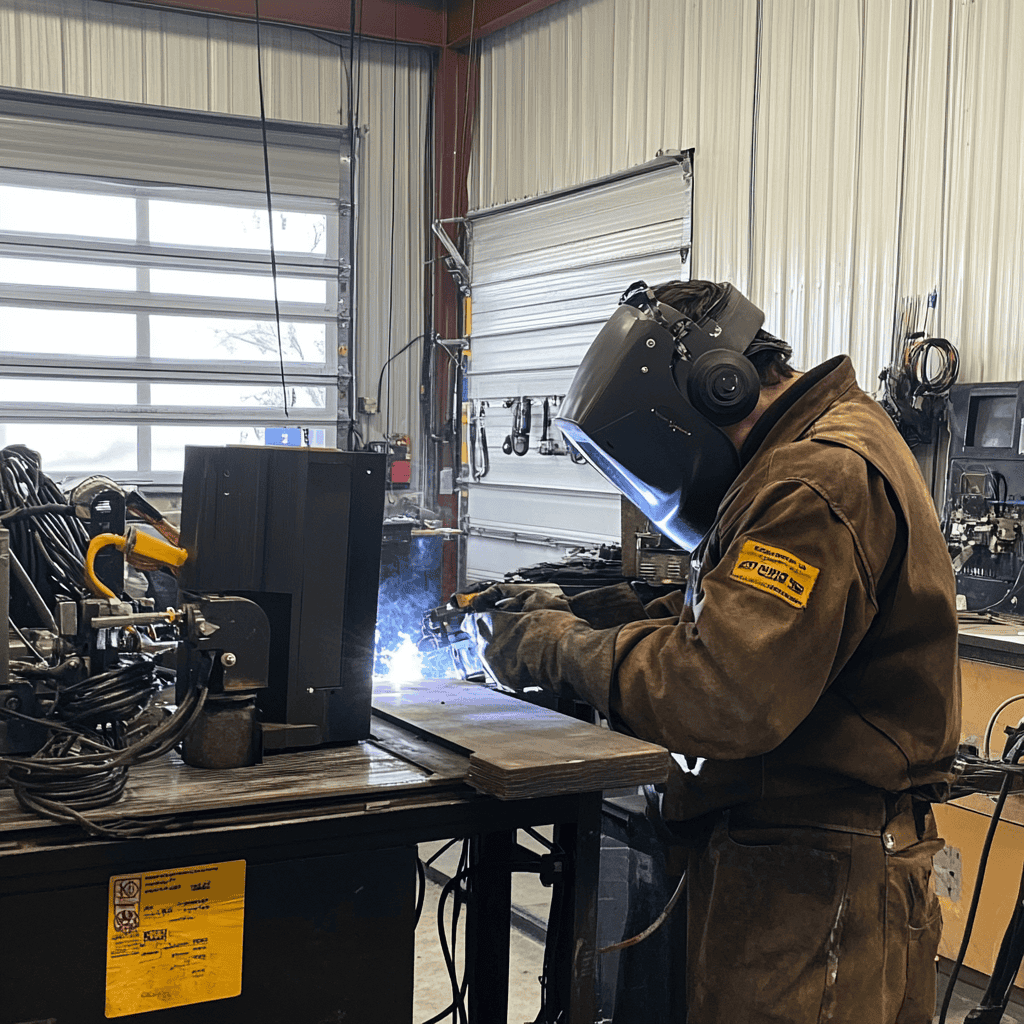

Apprenticeships are among the most effective ways to earn while you learn. These programs combine structured classroom instruction with on-the-job training, allowing participants to gain hands-on experience while receiving a wage. Sponsored by unions, trade organizations, or individual employers, apprenticeships are often highly competitive but well worth pursuing.

- Benefits: Apprentices earn as they train, typically starting at 50% to 70% of a journeyman’s wage. Over time, pay increases as skills and experience grow.

- Career Opportunities: Many apprenticeship programs lead directly to full-time employment, ensuring a smooth transition into the workforce upon completion.

- Specialized Training: Apprenticeships often focus on specific industries, such as shipbuilding, construction, or pipeline welding, giving students a head start in their desired field.

Co-op Programs

Many technical schools and community colleges offer cooperative education (co-op) programs, which integrate paid work placements into the academic curriculum. Students alternate between classroom instruction and practical work at partnering companies.

- Income and Experience: Co-op programs provide a regular income while helping students build professional connections and refine their skills in a real-world setting.

- Academic Credit: In many cases, co-op work placements count toward graduation requirements, allowing students to earn money without extending their program duration.

Internships

Paid internships with local companies are another excellent way for welding students to gain industry exposure while supplementing their income. Internships may be part-time during the school year or full-time over the summer, offering flexible opportunities for students to balance work and study.

- Practical Skills Development: Interns often work on actual projects, learning advanced techniques and problem-solving skills.

- Networking: Internships help students build relationships with industry professionals, which can lead to job offers after graduation.

- Diverse Opportunities: Internships can be found in industries ranging from automotive manufacturing to aerospace and construction.

Work-Study Programs

For students who qualify for federal financial aid, work-study programs provide a convenient way to earn money on campus. These jobs are typically related to the student’s field of study, such as assisting instructors, maintaining workshop equipment, or helping with administrative tasks in the welding department.

- Convenience: Work-study jobs are usually located on campus or nearby, making them easily accessible for students.

- Flexible Hours: These positions often accommodate students’ class schedules, ensuring they can prioritize their education while earning money.

- Skill Development: Work-study roles in welding departments can reinforce classroom learning and provide additional practice with tools and equipment.

Part-Time Welding Jobs

Some students take on part-time welding jobs while attending school, especially those with prior welding experience. Local fabrication shops, construction companies, or manufacturers may offer entry-level positions or weekend shifts that align with students’ schedules.

- Real-World Application: These roles allow students to apply classroom knowledge in practical settings, boosting their confidence and competence.

- Earnings: Part-time welding jobs often pay competitive hourly rates, helping students cover their tuition and living expenses.

Military Programs

For those with a military background or active-duty status, programs like the GI Bill can cover welding school tuition and provide a living stipend. Additionally, military-affiliated students may find specialized training programs that combine military service with technical education, ensuring a steady income during their studies.

Summary

While traditional welding schools don’t typically pay students, apprenticeships, co-op programs, internships, work-study opportunities, and part-time jobs offer viable ways to earn while learning. By exploring these options, students can reduce the financial burden of education and gain valuable experience that sets them apart in the competitive welding industry.

How Apprenticeships Differ from Welding School

Comparing Apprenticeships and Welding School: Pathways to a Welding Career

When deciding between welding school and an apprenticeship, it’s important to understand how each pathway shapes your learning experience, financial situation, and career prospects. While both can lead to successful careers in welding, they cater to different needs and goals.

Apprenticeships: Learn and Earn

Apprenticeships are a traditional and highly effective way to enter the welding profession. From day one, apprentices are considered employees, earning a wage while training under experienced welders. These programs typically last 3 to 5 years and include a combination of on-the-job training and classroom instruction.

- Financial Benefits: Apprenticeships provide immediate income, often starting at 50% to 70% of a journeyman welder’s wage. Pay increases incrementally as apprentices gain skills and experience, helping them financially support themselves throughout the program.

- Hands-On Experience: Apprenticeships are heavily focused on real-world applications, offering comprehensive hands-on training. Apprentices work on actual projects in industries such as construction, shipbuilding, or manufacturing, gaining practical expertise that’s hard to replicate in a classroom.

- Employer Sponsorship: Many apprenticeships are sponsored by unions or employers, covering training costs and often providing access to benefits like health insurance or retirement plans. This support reduces the financial burden of learning the trade.

- Time Commitment: While apprenticeships offer extensive training, they require a longer time commitment compared to welding school. The emphasis on gradual skill-building ensures apprentices are well-prepared for the workforce.

Welding School: A Focus on Education

Welding school provides a structured, education-focused approach to learning the trade. Programs can range from short-term certificate courses to comprehensive associate degree programs, combining theoretical knowledge with practical training in a controlled environment.

- Certifications and Credentials: Welding schools often prepare students for industry-recognized certifications, such as those offered by the American Welding Society (AWS). These credentials can boost employability and make graduates more competitive in the job market.

- Broad Knowledge Base: In addition to welding techniques, students learn about metallurgy, blueprint reading, and safety protocols. This broader foundation is especially beneficial for those aiming to specialize or advance in the field.

- Faster Completion: Welding school programs typically last 6 months to 2 years, allowing students to enter the workforce more quickly than the average apprenticeship. This accelerated timeline is appealing for individuals looking to start their careers sooner.

- Cost Considerations: Unlike apprenticeships, welding school requires an upfront financial investment, with tuition ranging from $3,000 to $25,000. However, scholarships, financial aid, and part-time jobs can help offset these costs.

Which Path is Right for You?

The choice between an apprenticeship and welding school depends on your priorities, learning style, and financial situation.

- For Immediate Income: Apprenticeships are ideal for those who need to earn a wage while training. The hands-on experience also appeals to individuals who learn best through practical application.

- For Accelerated Learning and Certifications: Welding school is better suited for those who prefer a shorter timeline and want to gain certifications to enhance their employability. It’s also a good option for individuals seeking a broader knowledge base or planning to specialize in advanced welding techniques.

The Bottom Line

Both apprenticeships and welding school offer valuable pathways to becoming a professional welder. Apprenticeships emphasize practical, on-the-job training with financial support, while welding schools focus on a faster, education-driven approach that prepares students for certification and specialization. Understanding the key differences can help aspiring welders choose the path that best aligns with their career goals and personal circumstances.er to complete.

Employer-Sponsored Training

Some companies offer employer-sponsored training programs, covering the cost of welding school in exchange for a work commitment after graduation. This option allows students to focus on their studies without worrying about tuition fees and guarantees a job upon completion. Industries like manufacturing, oil and gas, and construction often provide these opportunities. While this arrangement can be beneficial, it’s important to carefully review the terms, such as the required length of employment with the sponsoring company.

Financial Aid Options for Welding School

Paying for welding school can feel overwhelming, but a variety of financial aid options can help make your education more affordable and manageable. These resources not only reduce out-of-pocket expenses but also allow students to focus on their training without excessive financial stress.

Grants and Scholarships

Grants and scholarships are among the best financial aid options for welding students because they don’t need to be repaid.

- Trade Association Scholarships: Organizations like the American Welding Society (AWS) and local trade unions often provide scholarships specifically for students pursuing careers in welding. These awards can range from a few hundred to several thousand dollars.

- School-Specific Grants: Many technical schools and community colleges offer grants to eligible students based on financial need or academic performance.

- Industry Sponsorships: Some companies sponsor scholarships for students who commit to working for them after graduation, effectively combining financial aid with job placement.

Applying for multiple grants and scholarships can significantly reduce your tuition costs, making welding school much more accessible.

Loans

While loans do require repayment, they can provide the upfront funds needed to cover tuition, equipment, and living expenses.

- Federal Student Loans: These often have lower interest rates and more flexible repayment plans compared to private loans. Eligibility is determined through the Free Application for Federal Student Aid (FAFSA).

- Private Loans: Available through banks and credit unions, private loans can cover costs not met by federal aid. However, they typically have higher interest rates and stricter terms, so they should be considered carefully.

Understanding the long-term commitment of loan repayment is crucial before borrowing, but loans can bridge the gap when other forms of aid are insufficient.

Veterans Benefits

Military veterans have access to robust educational benefits through programs like the GI Bill.

- Tuition and Fees: The GI Bill often covers the full cost of welding education, including tuition, certification exams, and training materials.

- Housing Allowances: Veterans may also receive monthly stipends to cover living expenses while attending school.

- On-the-Job Training: Some veterans’ programs include apprenticeship or co-op opportunities that combine learning with earning.

Veterans can significantly reduce or even eliminate the financial burden of welding school, making it a great option for those who qualify.

Employer Reimbursement Programs

Some employers offer tuition reimbursement for employees pursuing relevant education. If you’re already working in a related field, check with your employer to see if they provide financial support for welding training.

Balancing Work and Welding School

For students who need to work while attending welding school, finding the right balance between employment and education is key to succeeding in both.

Part-Time Welding Jobs

Many students find entry-level positions in welding while completing their education. These jobs not only provide income but also offer valuable hands-on experience that complements classroom learning.

Freelance or Side Jobs

If you have other trade skills, such as carpentry or general metalwork, consider taking on freelance projects. These roles often offer flexible schedules, allowing you to work around your class hours.

Evening or Weekend Classes

Many technical schools and community colleges offer evening or weekend welding classes. These schedules are designed for working students and provide the flexibility needed to maintain a part-time job during the week.

By carefully managing your time and selecting opportunities that align with your career goals, you can earn money while building your skills and advancing your education.

The Return on Investment

One of the most compelling reasons to invest in welding education is the fast return on investment (ROI).

Quick Entry into the Workforce

Welding school programs typically last 6 months to 2 years, meaning students can start earning sooner than those pursuing four-year degrees.

Competitive Salaries

Welders often start with salaries ranging from $40,000 to $60,000 annually, with opportunities to earn more in specialized fields like underwater welding or aerospace. Compared to other professions requiring similar levels of education, welding offers high earning potential.

Career Longevity and Growth

The demand for skilled welders remains strong across industries such as construction, manufacturing, and energy. This stability, coupled with opportunities for advancement through certifications and specialization, ensures that welding remains a reliable and lucrative career path.

By choosing welding school and leveraging financial aid options, students can achieve a solid foundation for a high-paying career with minimal debt, making it a smart investment in their future.

Conclusion

While welding school doesn’t typically pay students, there are numerous ways to earn money while pursuing your education. Apprenticeships, co-op programs, internships, and work-study opportunities provide income and valuable experience. Employer-sponsored training and financial aid can further alleviate costs, making welding education more accessible. With its strong earning potential and high demand, investing in welding training is a smart choice that can lead to a fulfilling and financially rewarding career.

Additional Resources

Get your welding gear here.